|

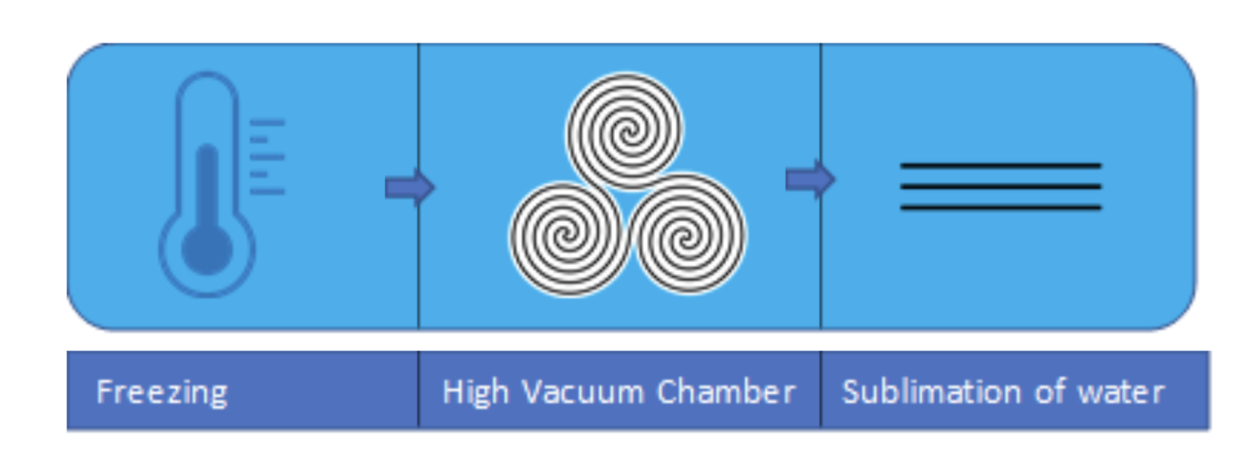

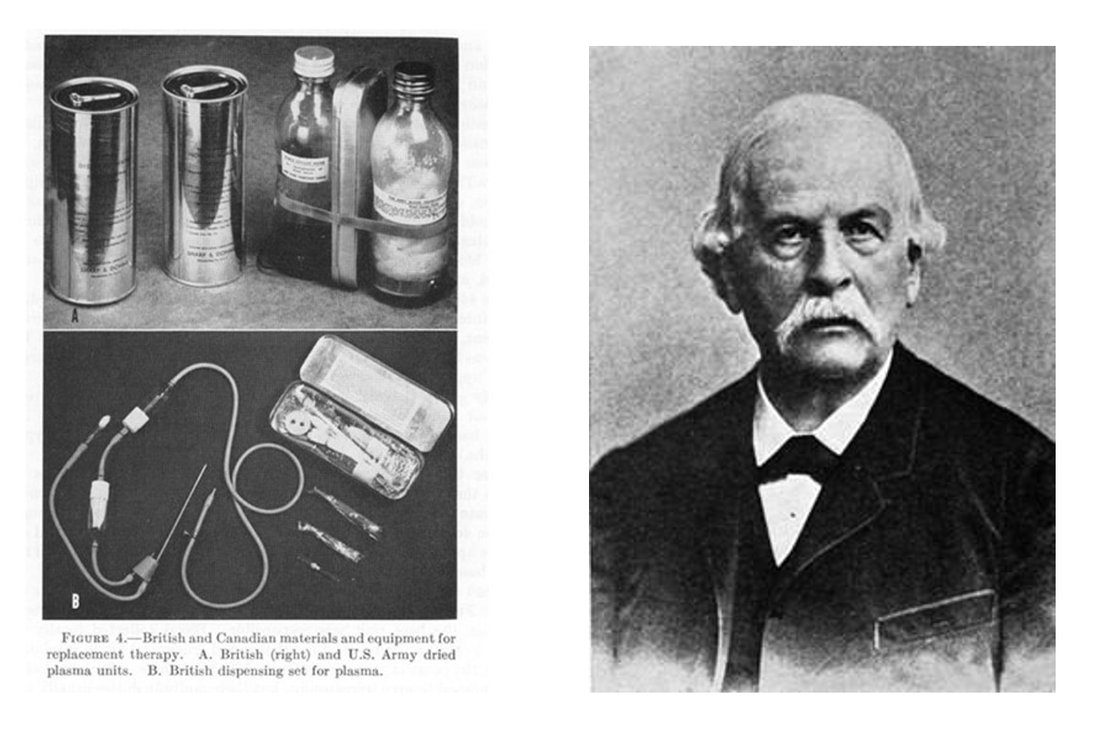

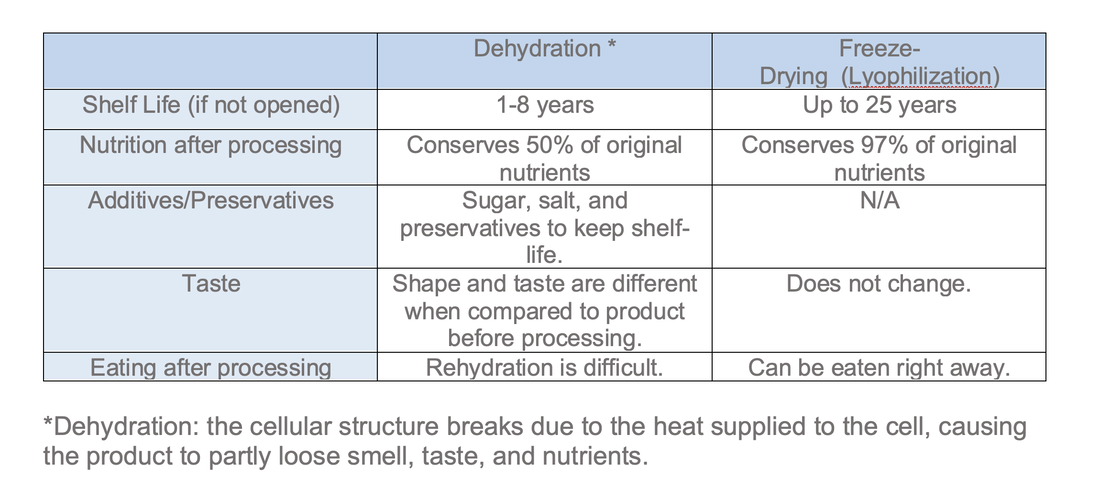

By: B. Lucio Picture from: https://www.thoughtco.com/lyophilization-preserving-biological-material-375590 As we all know, food is a very important part of our lives, and without it, we cannot survive. However, when the topic is going to space, many questions come to mind. Have you ever stopped to think how astronauts survive days or even years in space with the same food stock? Lyophilization is the answer. First of all, what is lyophilization? Lyophilization is a low temperature dehydration process which works by freezing a product, subjecting it to a high vacuum (reaching almost absolute vacuum) and removing its ice via sublimation. Another name for this process is "Freeze-Drying". Lyophilization is the only conservation process where the original nutrients, shape and properties are conserved. Although this sound all new and exciting, it is not. The truth is that this is an old technique. Lyophilization was invented in 1890 by Richard Altmann, who used it to conserve plant and animal tissues. With the beginning of World War II, scientists realized that they would not be able to conserve blood plasma due to the lack of refrigeration, so they used lyophilization; a simple and safe way to conserve the fluid. During the 1950’s and 1960’s industries such as the pharmaceutical industry began exploring the field of lyophilization, starting by the lyophilization of live virus vaccines. Around this time, the space race commenced. Who would get to space first? Well, quite honestly, without proper food, no one would. It is vital to keep the space crew healthy, particularly given that the duration of the mission might be undetermined. So, the food must be durable and nutritious. No conservation process can preserve both aspects, durability, and original nutritional properties, in room temperature, except for lyophilization. Do other processes not work? They do, but not as effectively as lyophilization. Take more common processes as examples, such as dehydration which consists of removing the water using evaporation. There is one main reason food must go under processing before going to space: durability. Food is made of up to 90% of water, and after a certain time, the microorganisms use the water within it to multiply themselves and provoke a chemical reaction, for energy and growth, therefore, this natural process causes the food to decay. Freeze dried food can be found in a supermarket, however they are more expensive products, considering that the shelf life is superior when compared to any other process that removes water. The process is sometimes used to conserve seasonal fruits. Lately, with the increase of productivity of fruits and vegetables, freeze-drying has been used to save the crop. More scientifically, in a fast and extremely low temperature freezing, the structure of the cell is preserved, unaltered, forming micro crystals inside the cell and thus preserving the product after sublimation. Lyophilization is a fascinating technology which few people know about, even though it has been around for a century. Over time, humans have found many ways to take advantage of this technology, from the most diverse areas of study, including feeding astronauts in space. Lately, scientists have been developing the most extraordinary ideas involving freeze-drying ideas, who knows what they will turn out to be? HOW IT EXACTLY HAPPENS : STEP BY STEP Industrial Step by Step This is an expensive technique, and few factories have the machine. Of course, in factories the process must be quick and efficient (meaning more quantity in less time) so machines are enormous and have capacity for various products at once. For better efficacy, this process is normally done in more than one machine. Step 1: Washing and Asepsis of Products Step 2: Pre treatment This means any type of treatment that must be done to the food before undergoing through freeze-drying, including chopping and sizing. Step 3: Freezing This step could be completed in regular industrial freezers; however, the process must be quick (as said above) so, many machines use “Ultra-Fast Freezing Chambers.” The fast chamber uses liquid nitrogen to maintain temperatures immensely below zero, therefore, the freezing stage is quicker. Step 4: Freeze Drier The frozen food is taken into a high vacuum chamber in which the ice is removed via sublimation. Step 5: Sealing The processed food must be packed into suitable air-sealed packages for improved shelf-life, especially considering that it could go to the supermarket or more unusual places such as space. STEP BY STEP AT HOME: Household Freeze-Dryer This is a great option for healthier and easier eating at home, bearing in mind that finding freeze-dried products at the supermarket is not as easy. Before buying a freeze drier, there some things to keep in mind, but especially that the process takes many hours, ranging from 20-40 hours (about 1 and a half days). But overall, it can be a promising idea even though it takes time and care. Step 1: Prepare food for processing This may involve chopping larger foods into smaller pieces for better results. Berries for example, can be left without chopping. Step 2: Insert food into Freeze-Dryer As simple as placing the items with spacing (so they do not touch) on the trays and setting the machine to complete the process. Freeze-dryers are automatic, they freeze and remove water from the products in one machine only. Another option would be to use a regular freezer and then a household vacuum chamber to remove water, however this option is more laborious. Step 3: Remove the processed food

After the process is completed, the food must be placed into air sealed containers for better shelf-life. Sources: https://en.wikipedia.org/wiki/Freeze-drying#:~:text=Freeze%20drying%2C%20also%20known%20as,that%20evaporate%20water%20using%20heat. https://www.nasa.gov/feature/facts-and-figures/ https://www.popularmechanics.com/home/food-drink/a24825856/freeze-dry-food/ https://airandspace.si.edu/exhibitions/apollo-to-the-moon/online/astronaut-life/food-in-space.cfm#:~:text=the%20lunar%20surface.-,Freeze%2DDried%20Space%20Food,placed%20into%20a%20vacuum%20chamber.&text=After%20rehydration%2C%20the%20food%20was,tube%20stored%20in%20the%20package. https://edition.cnn.com/2019/07/19/world/apollo-space-food-history-scn/index.html https://en.wikipedia.org/wiki/Space_food#Processing https://www.spscientific.com/freeze-drying-lyophilization-basics/ https://www.smithsonianmag.com/science-nature/again-and-again-in-world-war-ii-blood-made-the-difference-1-32174495/

0 Comments

Leave a Reply. |

Categories

All

Archives

June 2024

|